Contact us for more information.

Contact- Description

- Standard equipment

- Gallery

- Blog

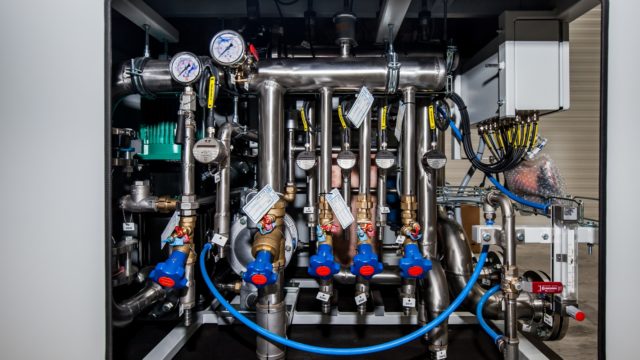

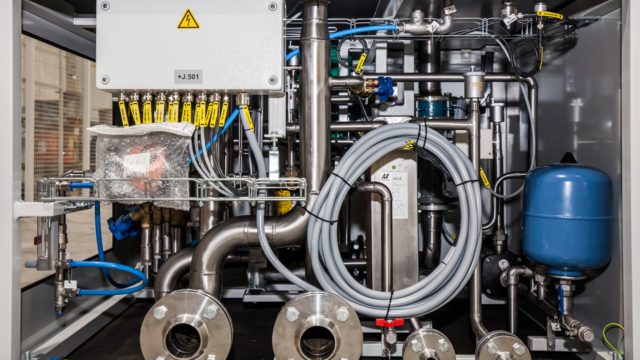

The cooling station ICHS is designed as a stand-alone unit, which can provide cooling water distribution for various number of technological equipment circuits. Each zone is equipped with balancing valve at device's outlet. There is a flow switch and a temperature sensor at input. The circuits are connected to the hoses with hose fittings.

The cooling unit is delivered without control system, it is equipped with necessary electric sensing devices. They are wired to a common terminal block (Junction box). Process water inlets and outlets are located on the bottom of unit.

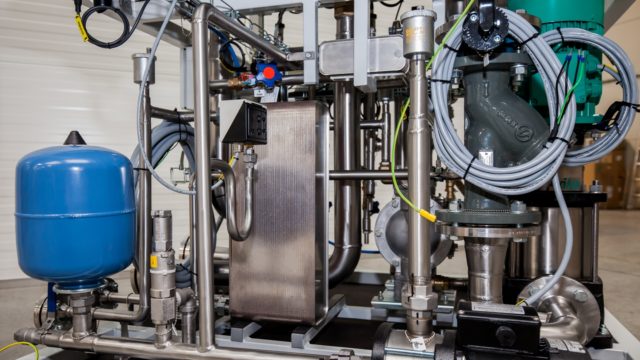

Access to balancing valves, flow switches, temperature sensors, rotameter and other valves is on the front side. The inlet and outlet of cooling water and emergency cooling water is located on the right side. In the upper part of device there is a tank designed for circulating process water. To the water in tank is added argon to treat the water. For the best effect, the gas is blown through the device that produces small bubbles. The tank is equipped with an air filter and a refill inlet on the top. There are drain valve, level sensor and temperature sensor on the bottom of tank.

In case of power failure, the unit is equipped with an emergency pump driven by compressed gas (argon), which ensures the necessary cooling of process water. The emergency pump is parallel to the main pump.

- Balancing valves

- Temperature sensors

- Flow switches

- Pressure sensor

- Manometer

- Junction box

- Rotameter

- Water tank

- Emergency circuit

-

Company IPECON, s.r.o. has created, implemented and used Integrated Management System (IMS). The implementation of activities, procedures and processes in IMS are made in accordance with standards ...

More

-

Based on the audit performed, the certification body for quality systems (TUV Rheinland) confirmed the implementation and application of a quality system that meets the requirements of the European Directive 2014/68 / EU. IPECON,…

More

-

This part of ISO 3834 specifies the complete quality requirements for fusion welding of metallic materials, both under shop conditions and at the installation sites. At IPECON,…

More

-

Electric forklift STILL RX60-50 helps us with increased needs of loads handling. The forklift is manufactured according to the latest technological standards. It uses front wheel drive ...

More

-

We have purchased a new Pneumatic Stand Pointing Machine with swing arm, which allows us to increase our work productivity and production efficiency of our products. The basic parameters are:…

More

-

In order to optimize welding work, we have purchased this system. The basis of the kit are welding tables, to which are fastened with special fastening pins a lot of…

More

-

For more than 20 years, the history of IPECON has been linked to our own production of our products. A brief summary of the main milestones of this period, from which it is clear…

More

-

A long-term standard in IPECON, s.r.o. is the labeling of products with quality product labels containing identification and basic technical data. Control and signaling elements, cables and more…

More

-

When exporting temperature stations to Thailand, we needed to provide above-standard export packaging of equipment. The proposal took into account several factors such as destination, estimated storage time, climatic…

More

-

We bought a new Sandbox 1200 l, which has an extra large working area of 1300 x 1180 x 850 mm and a large side door. Two guns…

More

-

After problems with stability and insufficient performance of the original program, a new solution for the design department was sought. Alternative solutions were tested and based on good experience was…

More

-

Continuous increase in production volume did not allow us to work only in the existing premises. That is why we have expanded our assembly and storage space by an area of…

More

-

We moved the warehouse of production components to new larger area. The receipt and expedition of material for individual orders is more efficient.

More

-

Looking for a reliable supplier and partner? IPECON has been a reliable partner for its customers for 25 years. We offer years of experience in the field of heat engineering and power engineering…

More